Photovoltaic SCADA

Photovoltaic SCADA

WHAT IS IT?

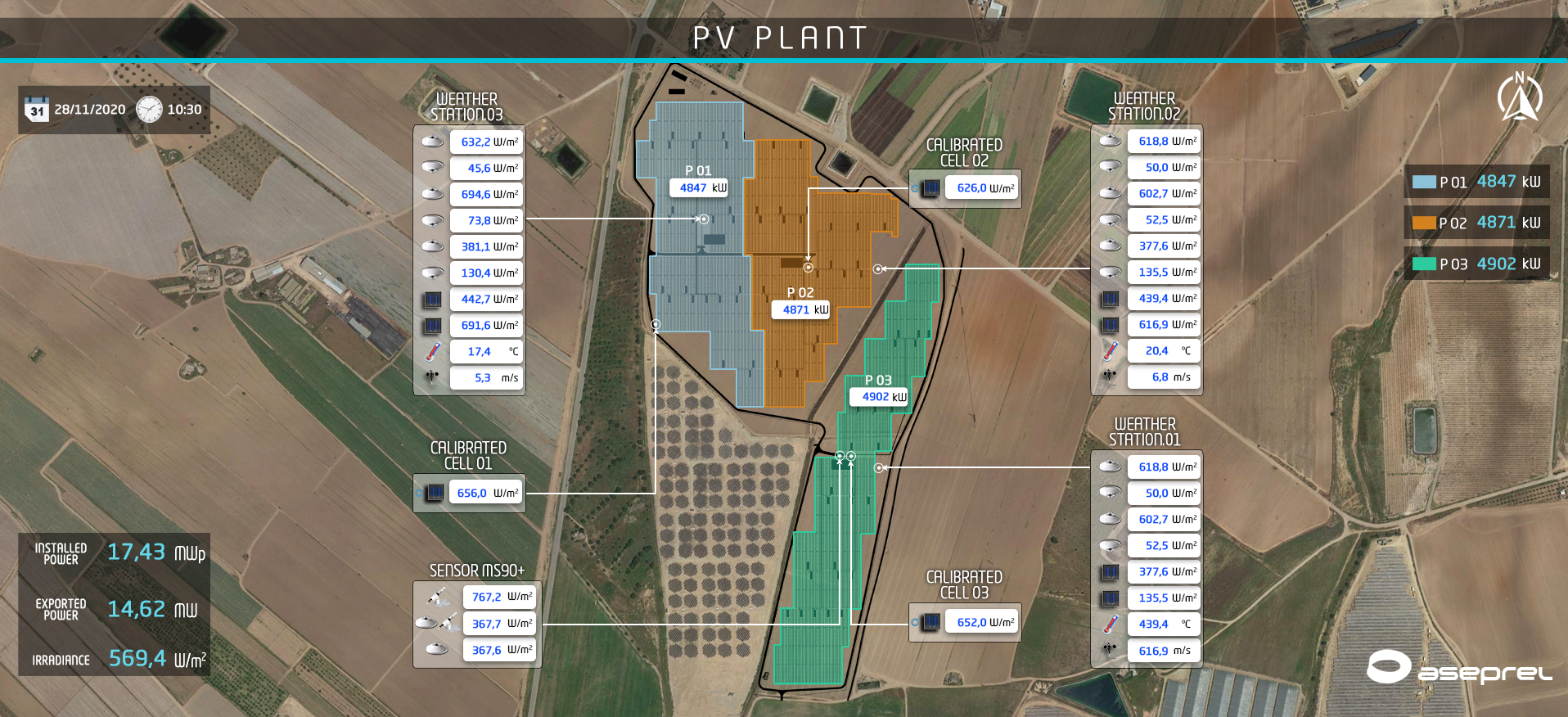

SCADA is the Supervision, Control and Data Acquisition application that helps improve remote decision-making.

At Aseprel, we implement our SCADA system in photovoltaic plants, thus providing a real-time and historical monitoring and control tool for process optimization.

The development of the application is based on the client's needs, creating visualization screens, reports, alarms according to consumption, processes, devices or any other requirement.

By installing data receivers at various points of the installation to be monitored, we can know what is happening and even control the opening or closing of resources.

At Aseprel we offer solutions that facilitate the management of electricity consumption and monitoring of generation systems.

IMPLEMENTATION

We start with the design and installation of the communications network, cabinets and equipment; We perform the monitoring of the equipment integrated into the SCADA system and customize the application according to the customer's needs:

- Customized screens: We ensure complete visualization through intuitive, easy-to-use and high-quality screens.

- Production control: We account for each of the measuring points and useful hours of production.

- Real-time monitoring: We provide complete visualization with alarms and notices located instantly.

- Historicals generated in the SCADA system: We have reports that show the total energy generated per desired period, the PR calculation and other variables of interest.

- Hosting service: We store your data on our servers, while we provide your direct online access.

RESULTS

Photovoltaic SCADA is the necessary tool for proper maintenance of facilities, allowing:

- Optimize processes to improve production

- Reduce costs. By gaining control of spending, you can save on resources and achieve maximum efficiency.

- Have a database with stored information.

- Carry out audits in real time analyzing the different parameters on which the process depends.

- Regarding the environment, the urgent need to find solutions has required the integration of measurement systems, which allow monitoring the self-supply process and prioritizing consumption . In addition, real-time monitoring systems allow information to be obtained at all times, production incidents, including impact due to CO2 reduction.

SCADA is the Supervision, Control and Data Acquisition application that helps improve remote decision-making.

At Aseprel, we implement our SCADA system in photovoltaic plants, thus providing a real-time and historical monitoring and control tool for process optimization.

The development of the application is based on the client's needs, creating visualization screens, reports, alarms according to consumption, processes, devices or any other requirement.

By installing data receivers at various points of the installation to be monitored, we can know what is happening and even control the opening or closing of resources.

At Aseprel we offer solutions that facilitate the management of electricity consumption and monitoring of generation systems.

We start with the design and installation of the communications network, cabinets and equipment; We perform the monitoring of the equipment integrated into the SCADA system and customize the application according to the customer's needs:

- Customized screens: We ensure complete visualization through intuitive, easy-to-use and high-quality screens.

- Production control: We account for each of the measuring points and useful hours of production.

- Real-time monitoring: We provide complete visualization with alarms and notices located instantly.

- Historicals generated in the SCADA system: We have reports that show the total energy generated per desired period, the PR calculation and other variables of interest.

- Hosting service: We store your data on our servers, while we provide your direct online access.

Photovoltaic SCADA is the necessary tool for proper maintenance of facilities, allowing:

- Optimize processes to improve production

- Reduce costs. By gaining control of spending, you can save on resources and achieve maximum efficiency.

- Have a database with stored information.

- Carry out audits in real time analyzing the different parameters on which the process depends.

- Regarding the environment, the urgent need to find solutions has required the integration of measurement systems, which allow monitoring the self-supply process and prioritizing consumption . In addition, real-time monitoring systems allow information to be obtained at all times, production incidents, including impact due to CO2 reduction.